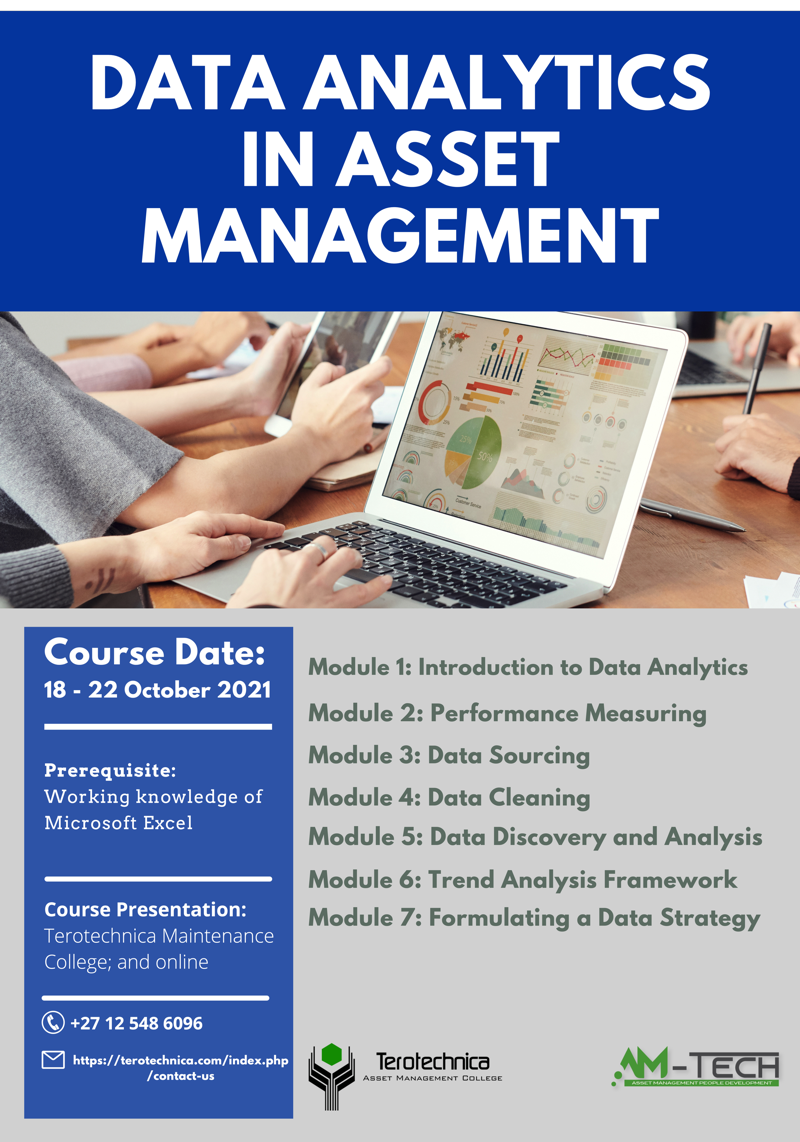

S809: Data Analytics in Asset Management

The analysis of data is one of the most important activities in modern asset management. It can make the difference between success and failure.

1. Introduction

The Data Analytics in Maintenance course aims to create an appreciation of analytics in the context of a rapidly increasing data driven world. The South African mining industry was historically characterized conventional labour-intensive mines. Technology has been widely adopted and in 2021, most new mining projects are heavily mechanized and rely on various technologies, albeit with different levels of adoption.

This wave of mechanization has drastically increased complexity in terms of:

- supply chain systems: machines have thousands of parts and components

- training and skill development: the variety of assets are increasing fast

- cost: managing costs and operational efficiency has become more critical

- operational visibility: identifying operational bottlenecks in an environment with many complex coupled variables will need more methodical approach

These demands are not only applicable to maintenance aspects in mining, but also in any capital-intensive industries where equipment downtime and marginal changes in the operational expenditure can threaten the bottom line.

The course is a jargon-free practical guide to creating valuable and actionable insights to optimize the asset management effort. We have intentionally elected to create content that will accommodate learners with limited statistical training while limiting the primary tool of analysis to Microsoft Excel. The course will cover the whole analytics process using practical hands-on examples.

2. Course Duration

The material is taught in 5 days with a daily 8 hour per day schedule.

3. Prerequisite

Learner should have a working knowledge of computers ( internet, Microsoft Excel and email).

4. Course Content

4.1 Module 1: A brave new world

Data analytics and concepts are introduced. The learner is exposed to how world-class maintenance professionals are using data strategically in business. The data science analytics process is explained and contrasted to how the course aims to address the various stages of the analytics process.

Topics:

- The analytics process

- Business case studies

- The changing maintenance landscape

- Maintenance 4.0 technologies

- Organizational data analytics maturity

4.2 Module 2: Performance Measuring

This module discusses how and where an organization can begin its digitalization journey. The performance measurement is a natural starting process in starting up a concerted analytics process. The themes covered outline how an organization can effectively use performance measurements to identify risks, opportunities, foster innovation and drive continuous improvement.

Topics:

- Maintenance and operational indicators

- How maintenance key performance indicators (KPIs) influence strategic outcomes

- How to make winning KPIs

- How to make winning KPIs

- How to dig deeper in the KPIs to understand what is driving them

- Understanding historical and predictive indicators

- Planning for effective performance measures

- Cascading strategic objectives through performance measures

4.3 Module 3: Data Sourcing

This module introduces the Extract, Transform and Load tool through Power Query. This tool is used to automate much of the data sourcing process and to a extend the data cleaning process. We use hands-on practical data to work on.

Topics:

- Various types of structured data and how to digitalize them

- Data definitions through the knowledge pyramid

- Meta data management

- How to use Power Query to;

- Connect to various sources (online, folders, worksheets and database)

- How to transform data and automate the data preparation

- How to reduce manual operation when merging and appending data

- How to make regular reports to self-update and safe valuable time

4.4 Module 4: Cleaning Data

Most collected digital data that is not analysed is in the format that is not easy to manipulate. It could be some parts are missing, aggregated, the format is not usable to the analyst and no consistency in how the records are captured. This chapter gives the learner tools to make the data usable for the analytical process.

Topics:

- Dealing with the top 5 data quality dimensions:

- Accuracy

- Completeness

- Consistency

- Validity

- Uniqueness

Practical examples on MS Excel and understanding functions to clean data

4.5 Module 5: Data Discovery and Analysis

Analysis is the heart of the analytics process. In this chapter we use methods to make the data to tell a compelling story. This module uses a practical examples where various data sources are integrated and prepared to solve real maintenance problems. Although many operations have some form of visualization reporting, the student is introduced to diagnostics and predictive analytics processes.

Topics:

- Framing maintenance questions into analytical projects

- Creating focus to find maintenance insights

- Data aggregation techniques

- Creating visuals that tell a compelling story

- Going beyond descriptive analytics

- Diagnostic analytics and finding relationships within the data

- Prescriptive diagnostics: how to create data models

- Introduction to regression

- Time-series analysis

- Developing hypothesis

- Practical exercises to find meaning in otherwise latent data

4.6 Module 6: Trend Analysis Framework

This framework demands all the skills picked up from Module 3 to Module 5. It covers a novel method to track the consumption of 1000s of parts in a non-graphical method. This ingenious trending method can be used to answer questions such as: what is pushing the cost curve, which failure modes are on the rise and which parts must we reduce or increase in the warehouses

Topics:

In an operation that uses 10,000+ individual coded items such as spare parts, raw material and fuel, an engineering manager is interested in understanding what is causing maintenance costs to rise in spite of many initiatives by the team. He ropes in an analyst to assist the reliability engineer to conduct a spend analytics project.

Tracking an individual item using time-series graphical plots may be adequate, however, when looking at 1000s of items, a graphical approach becomes rather tedious because;

- Creating 1000s of graphs is not practical to do or interpret

- Graphical information still needs further analysis to determine the trend

- Graphical information methods cannot be filtered or manipulated

This analysis framework opens up many possibilities in analysing trends in a powerful method.

4.7 Module 7: Formulating a Data Strategy

Data analytics is prevalent in some form in every enterprise. However, the maturity and benefits derived are not consistent. In the maintenance realm, there are countless amount of data generated within the CMMS system, the ERP and the production environs. This module shortly provides a brief overview on how an organisation as a whole or a maintenance department can take intentional steps to make the most of the data in the organization through crafting a Data Strategy. Aspects of the Data Strategy are discussed in a jargon-free manner. The discussions are aimed at maintenance professionals and not IT professionals.

Topics:

- What is a data strategy

- Benefits of conceptualizing a data strategy

- Data strategy formulation steps

- Questions to create a data-driven operation vision

- Reviewing the current data utility

- A brief overview of what good data maturity looks like

- The four types of analytics

- Practical maintenance data considerations

- Data governance and how to leverage ICT models

- Creating a roadmap

- Typical Data Analytics jobs

- Typical Data Analytics software and tools

Who Should Attend

This course is intended for anyone who has to work with data and understand the fundamental meaning of data. These include Asset Managers, Maintenance Managers, Maintenance Engineers, Managers in control of Asset Management, Managers in control of Maintenance Stockkeeping and Purchasing, Maintenance Supervisors, Maintenance Planners, and many others. It can play an important role to prepare maintenance and operational personnel to understand the fundamental asset management/maintenance organisation's problems and enable them to manage and direct the organisation successfully.

|

Credits 12*, level 6**

* The course comprises 60 hours of study, of which 40 hours are in class, with a further 20 hours spent on completing a work related assignment.. **Higher Diploma level |

|

Course information at a glance 2020

Important note: If this table and the calendar on the right interferes with each other, press Control+minus repeatedly to reduce the font size, until you can see well enough.

|

|

|||||

|

COURSE SCHEDULE : 2020 |

|||||

|

|

|

|

|

||

|

|

|

|

|

||

|

Course code |

Course description |

Duration Days |

Dates |

Cost |

|

|

Excl VAT |

|||||

|

C101 |

2 days |

1st course: 27 - 28 January |

R 6 399 |

||

|

2nd course: 17 - 18 February |

|||||

|

3rd course: 15 - 16 April |

|||||

|

4th course: 13 - 14 May |

|||||

|

5th course: 22 - 23 June |

|||||

|

6th course: 20 - 21 July |

|||||

|

7th course: 12 - 13 August |

|||||

|

8th course: 21 - 22 September |

|||||

|

9th course: 27 - 28 October |

|||||

|

10th course: 10 - 11 November |

|||||

|

C201 |

5 days |

1st course: 27 - 31 January |

R 15 999 |

||

|

2nd course: 24 - 28 February |

|||||

|

3rd course: 23 - 27 March |

|||||

|

4th course: 4 - 8 May |

|||||

| 5th course: 1 - 5 June |

|||||

| 6th course: 29 June - 3 July |

|||||

| 7th course: 27 - 31 July |

|||||

| 8th course: 24 - 28 August |

|||||

| 9th course: 28 September - 2 October |

|||||

| 10th course: 26 - 30 October | |||||

|

11th course: 23 - 27 November |

|||||

|

C301 |

5 days |

1st course: 20 - 24 January |

R 15 999 |

||

|

2nd course: 17 - 21 February |

|||||

|

3rd course: 16 - 20 March |

|||||

| 4th course: 20 - 24 April | |||||

|

5th course: 18 - 22 May |

|||||

|

6th course: 22 - 26 June |

|||||

|

7th course: 20 - 24 July |

|||||

| 8th course: 17 - 21 August |

|||||

| 9th course: 14 - 18 September |

|||||

| 10th course: 12 - 16 October |

|||||

| 11th course: 9 - 13 November |

|||||

|

12th course: 7 - 11 December |

|||||

|

C302 |

5 days |

1st course: 10 - 14 February |

R 15 999 |

||

|

2nd course: 30 March - 3 April |

|||||

|

3rd course: 11 - 15 May |

|||||

| 4th course: 29 June - 3 July | |||||

|

5th course: 3 - 7 August |

|||||

| 6th course: 7 - 11 September | |||||

|

7th course: 19 - 23 October |

|||||

|

8th course: 30 November - 4 December |

|||||

|

C501 |

Maintenance Shutdown and Project Management (Please see footnote for computer requirement) |

5 days |

1st course: 3 - 7 February |

R 16 585 |

|

|

2nd course: 9 - 13 March |

|||||

| 3rd course: 20 - 24 April | |||||

|

4th course: 25 - 29 May |

|||||

| 5th course: 29 June - 3 July |

|||||

| 6th course: 3 - 7 August |

|||||

|

7th course: 28 September - 2 October |

|||||

|

8th course: 2 - 6 November |

|||||

|

9th course: 7 - 11 December |

|||||

|

C702 |

Reliability Engineering in Asset Management (Please see footnote for computer requirement) |

5 days |

1st course: 16 - 20 March |

R 17 805 |

|

| 2nd course: 11 - 15 May | |||||

|

3rd course: 27 - 31 July |

|||||

| 4th course: 14 - 18 September | |||||

|

5th course: 16 - 20 November |

|||||

|

C901 |

Maintenance Practice for Asset Management Engineers |

5 days |

1st course: 24 - 28 February |

R 16 599 |

|

|

2nd course: 30 March - 3 April |

|||||

|

3rd course: 22 - 26 June |

|||||

| 4th course: 31 August - 4 September | |||||

|

5th course: 26 - 30 October |

|||||

|

C902 |

5 days |

1st course: 10 - 14 February |

R 16 599 |

||

|

2nd course: 4 - 8 May |

|||||

| 3rd course: 13 - 17 July |

|||||

|

4th course: 12 - 16 October |

|||||

|

C903 |

RCM Facilitation and Analysis |

5 days |

1st course: 20 - 24 January |

R 16 599 |

|

|

2nd course: 2 - 6 March |

|||||

|

3rd course: 18 - 22 May |

|||||

| 4th course: 6 - 10 July |

|||||

|

5th course: 7 - 11 September |

|||||

|

6th course: 2 - 6 November |

|||||

|

C904 |

RCM ProAktiv, Advanced Reliability Centred Maintenance (Please see footnote for computer requirement)

Please note that this course has a pre-requirement. Students

This is to ensure that participants will adequately cope with the |

5 days |

R 16 599 |

|

|

|

|

|||||

| 1st course: 25 - 29 May | |||||

| 2nd course: 31 August - 4 September | |||||

|

S801 |

Reliability Centred Maintenance |

3 days |

1st course: 20 - 22 January |

R 10 205 |

|

|

2nd course: 2 - 4 March |

|||||

|

3rd course: 18 - 20 May |

|||||

|

4th course: 6 - 8 July |

|||||

| 5th course:7 - 9 September |

|||||

|

6th course: 2 - 4 November |

|||||

|

S802 |

3 days |

1st course: 4 - 6 February |

R 10 205 |

||

|

2nd course: 6 - 8 April |

|||||

|

3rd course: 27 - 29 July |

|||||

|

4th course: 6 - 8 October |

|||||

|

S803 |

5 days |

1st course: 27 - 31 January |

R 18 295 |

||

|

2nd course: 2 - 6 March |

|||||

|

3rd course: 20 - 24 April |

|||||

| 4th course: 8 - 12 June |

|||||

| 5th course: 13 - 17 July | |||||

|

6th course: 24 - 28 August |

|||||

|

7th course: 5 - 9 October |

|||||

|

8th course: 16 - 20 November |

|||||

|

S804 |

Decision Making in Maintenance |

5 days |

1st course: 3 - 7 February |

R 17 865 |

|

| 2nd course: 9 - 13 March | |||||

|

3rd course: 20 - 24 April |

|||||

|

4th course: 8 - 12 June |

|||||

| 5th course: 20 - 24 July | |||||

| 6th course: 31 August - 4 September | |||||

| 7th course: 12 - 16 October |

|||||

|

8th course: 23 - 27 November |

|||||

|

S805 |

2 days |

1st course: 23 - 24 January |

R 6 399 |

||

| 2nd course: 24 - 25 February | |||||

|

3rd course: 29 - 30 April |

|||||

| 4th course: 11 - 12 May | |||||

| 5th course: 1 - 2 June | |||||

| 6th course: 7 - 8 July | |||||

| 7th course: 12 - 13 August | |||||

| 8th course: 21 - 22 September | |||||

|

9th course: 3 - 4 November |

|||||

|

S808 |

3 days |

1st course: 29 - 31 January |

R 9 599 |

||

|

2nd course: 6 - 8 April |

|||||

|

3rd course: 17 - 19 June |

|||||

|

4th course: 18 - 20 August |

|||||

|

5th course: 20 - 22 October |

|||||

|

6th course: 8 - 10 December |

|||||

|

S811 |

3 days |

1st course: 11 - 13 February |

R 11 605 |

||

|

2nd course: 23 -25 March |

|||||

|

3rd course: 15 - 17 April |

|||||

|

4th course: 17 - 19 June |

|||||

|

5th course: 6 - 8 July |

|||||

|

6th course: 21 - 23 September |

|||||

|

7th course: 17 - 19 November |

|||||

|

S812 |

2 days |

1st course: 26 - 27 February |

R 6 399 |

||

|

2nd course: 26 - 27 March |

|||||

| 3rd course: 29 - 30 April |

|||||

|

4th course: 24 - 25 June |

|||||

|

5th course: 9 - 10 July |

|||||

|

6th course: 21 - 22 September |

|||||

| 7th course: 19 - 20 October | |||||

|

8th course: 1 - 2 December |

|||||

|

S813 |

Economical Replacement and Life Cycle Management |

5 days |

1st course: 17 - 21 February |

R 16 499 |

|

|

2nd course: 23 - 27 March |

|||||

| 3rd course: 25 - 29 May | |||||

| 4th course: 13 - 17 July | |||||

| 5th course: 7 - 11 September |

|||||

|

6th course : 26 - 30 October |

|||||

|

S820 |

What is Asset Management and how does it differ from |

2 days |

1st course: 19 - 20 February |

R 6 399 |

|

|

S821 |

3 days |

1st course: 22 - 24 July |

R 9 599 |

||

|

S822 |

3 days |

1st course: 21 - 23 October |

R 9 599 |

||

|

Diploma in Maintenance Management |

For comprehensive information on our choice of 5 diplomas, |

R 64 385 |

|||

|

please visit our website www.terotechnica.com |

|||||

|

|

|

|

|

|

|

|

Footnote: Students enrolling for these courses: C501, C702, C901, C903, C904, S801, S804 and S813, must be in possession of their own laptop computers. Computers supplied by employers often have safety features installed which prevent students free access to all the programs and functions required for the course. |

|||||

|

|

|

|

|

|

|

|

In-house training: |

|||||

|

|

|

|

|

|

|

|

1. |

Please note that considerable savings, both in time and money, can be brought about by having any of the above courses presented in-house. Attractive discounts are offered. Please contact us for quotations. Terms and conditions apply. |

||||

|

|

|||||

|

2. |

Comprehensive information regarding all diplomas and courses is available on our website www.terotechnica.com |

||||

|

|

|

|

|

|

|

Course information at a glance 2019

Important note: If this table and the calendar on the right interferes with each other, press Control+minus repeatedly to reduce the font size, until you can see well enough.

|

|

|||||

|

COURSE SCHEDULE : 2019 |

|||||

|

|

|

|

|

||

|

|

|

|

|

||

|

Course code |

Course description |

Duration Days |

Dates |

Cost |

|

|

Excl VAT |

|||||

|

C101 |

2 days |

1st course: 28 - 29 January |

R 5 929 |

||

|

2nd course: 18 - 19 February |

|||||

|

3rd course: 18 - 19 March |

|||||

|

4th course: 15 - 16 April |

|||||

|

5th course: 20 - 21 May |

|||||

|

6th course: 24 - 25 June |

|||||

|

7th course: 22 - 23 July |

|||||

|

8th course: 5 - 6 August |

|||||

|

9th course: 25 - 26 September |

|||||

|

10th course: 28 - 29 October |

|||||

|

11th course: 13 - 14 November |

|||||

|

C201 |

5 days |

1st course: 14 - 18 January |

R 14 825 |

||

|

2nd course: 11 - 15 February |

|||||

|

3rd course: 11 - 15 March |

|||||

|

4th course: 8 - 12 April |

|||||

|

5th course: 13 - 17 May |

|||||

| 6th course: 10 - 14 June |

|||||

| 7th course: 8 - 12 July |

|||||

| 8th course: 19 - 23 August |

|||||

| 9th course: 9 - 13 September |

|||||

| 10th course: 7 - 11 October |

|||||

|

11th course: 25 - 29 November |

|||||

|

C301 |

5 days |

1st course: 21 - 25 January |

R 14 825 |

||

|

2nd course: 18 - 22 February |

|||||

|

3rd course: 25 - 29 March |

|||||

|

4th course: 13 - 17 May |

|||||

|

5th course: 3 - 7 June |

|||||

|

6th course: 1 - 5 July |

|||||

| 7th course:12 - 16 August |

|||||

| 8th course:16 - 20 September |

|||||

| 9th course:14 - 18 October |

|||||

| 10th course:11 - 15 November |

|||||

|

11th course: 9 - 13 December |

|||||

|

C302 |

5 days |

1st course: 11 - 15 February |

R 15 685 |

||

|

2nd course: 8 - 12 April |

|||||

|

3rd course: 20 - 24 May |

|||||

|

4th course: 29 July - 2 August |

|||||

|

5th course: 21 - 25 October |

|||||

|

6th course: 2 - 6 December |

|||||

|

C501 |

Maintenance Shutdown and Project Management (Please see footnote for computer requirement) |

5 days |

1st course: 4 - 8 February |

R 15 239 |

|

|

2nd course: 11 - 15 March |

|||||

|

3rd course: 13 - 17 May |

|||||

| 4th course: 22 - 26 July |

|||||

| 5th course:26 - 30 August |

|||||

|

6th course: 30 September - 4 October |

|||||

|

7th course: 18 - 22 November |

|||||

|

8th course: 9 - 13 December |

|||||

|

C702 |

Reliability Engineering in Asset Management (Please see footnote for computer requirement) |

5 days |

1st course: 25 February - 1 March |

R 16 195 |

|

|

2nd course: 10 - 14 June |

|||||

|

3rd course: 14 - 18 October |

|||||

|

C901 |

Maintenance Practice for Asset Management Engineers |

5 days |

1st course: 28 January - 1 February |

R 15 425 |

|

|

2nd course: 1 - 5 April |

|||||

|

3rd course: 1 - 5 July |

|||||

| 4th course: 2 - 6 September | |||||

|

5th course: 28 October - 1 November |

|||||

|

C902 |

5 days |

1st course: 28 January - 1 February |

R 15 425 |

||

|

2nd course: 4 - 8 March |

|||||

|

3rd course: 1 - 5 April |

|||||

|

4th course: 27 - 31 May |

|||||

| 5th course:15 - 19 July |

|||||

| 6th course:26 - 30 August |

|||||

| 7th course:14 - 18 October |

|||||

|

8th course: 25 - 29 November |

|||||

|

C903 |

RCM Facilitation and Analysis |

5 days |

1st course: 25 February - 1 March |

R 15 425 |

|

|

2nd course: 1 - 5 April |

|||||

|

3rd course: 3 - 7 June |

|||||

| 4th course:12 - 16 August |

|||||

|

5th course: 7 - 11 October |

|||||

|

6th course: 4 - 8 November |

|||||

|

7th course: 2 - 6 December |

|||||

|

C904 |

RCM ProAktiv, Advanced Reliability Centred Maintenance (Please see footnote for computer requirement)

Please note that this course has a pre-requirement. Students

This is to ensure that participants will adequately cope with the |

5 days |

R 15 425 |

|

|

|

|

|||||

|

1st course: 28 January - 1 February |

|||||

|

2nd course: 27 - 31 May |

|||||

| 3rd course: 2 - 6 September | |||||

|

S801 |

Reliability Centred Maintenance |

3 days |

1st course: 25 - 27 February |

R 9 495 |

|

|

2nd course: 1 - 3 April |

|||||

|

3rd course: 3 - 5 June |

|||||

|

4th course: 12 - 14 August |

|||||

| 5th course:7 - 9 October |

|||||

|

6th course: 4 - 6 November |

|||||

|

7th course: 2 - 4 December |

|||||

|

S802 |

3 days |

1st course: 25 - 27 March |

R 9 495 |

||

|

2nd course: 20 - 22 May |

|||||

|

3rd course: 29 - 31 July |

|||||

|

4th course: 16 - 18 September |

|||||

|

S803 |

5 days |

1st course: 21 - 25 January |

R 16 715 |

||

|

2nd course: 4 - 8 March |

|||||

|

3rd course: 27 - 31 May |

|||||

| 4th course:10 - 14 June |

|||||

|

5th course: 19 - 23 August |

|||||

|

6th course: 21 - 25 October |

|||||

|

7th course: 2 - 6 December |

|||||

|

S804 |

Decision Making in Maintenance |

5 days |

1st course: 4 - 8 February |

R 16 325 |

|

|

2nd course: 8 - 12 April |

|||||

|

3rd course: 24 - 28 June |

|||||

| 4th course:30 September - 4 October |

|||||

|

4th course: 9 - 13 December |

|||||

|

S805 |

2 days |

1st course: 18 - 19 March |

R 5 929 |

||

|

2nd course: 17 - 18 April |

|||||

| 3rd course: 5 - 6 August | |||||

| 4th course: 25 - 26 September | |||||

|

5th course: 4 - 5 November |

|||||

|

S808 |

3 days |

1st course: 30 January - 1 February |

R 8 895 |

||

|

2nd course: 23 - 25 April |

|||||

|

3rd course: 18 - 20 June |

|||||

|

S811 |

3 days |

1st course: 14 - 16 January |

R 10 895 |

||

|

2nd course: 25 -27 March |

|||||

|

3rd course: 23 - 25 April |

|||||

|

4th course: 18 - 20 June |

|||||

|

5th course: 8 - 10 July |

|||||

|

6th course: 25 - 27 September |

|||||

|

7th course: 18 - 20 November |

|||||

|

S812 |

2 days |

1st course: 17 - 18 January |

R 5 929 |

||

|

2nd course: 11 - 12 March |

|||||

| 3rd course:2 - 3 May |

|||||

|

4th course: 24 - 25 June |

|||||

|

5th course: 11 - 12 July |

|||||

|

6th course: 25 - 26 September |

|||||

|

7th course: 21 - 22 October |

|||||

|

S813 |

Economical Replacement and Life Cycle Management |

5 days |

1st course: 18 - 22 February |

R 15 225 |

|

|

2nd course: 15 - 19 July |

|||||

| 3rd course:9 - 13 September |

|||||

|

3rd course : 28 October - 1 November |

|||||

|

S820 |

What is Asset Management and how does it differ from |

2 days |

1st course: 15 - 16 April |

R 5 929 |

|

|

2nd course: 15 - 16 August |

|||||

|

S821 |

3 days |

1st course: 24 - 26 July |

R 8 895 |

||

|

S822 |

3 days |

1st course: 23 - 25 October |

R 8 895 |

||

|

Diploma in Maintenance Management |

For comprehensive information on our choice of 5 diplomas, |

R 59 615 |

|||

|

please visit our website www.terotechnica.com |

|||||

|

|

|

|

|

|

|

|

Footnote: Students enrolling for these courses, C501, C702, C901, C903, C904, S801, S804 and S813, must be in possession of their own laptop computers. Computers supplied by employers often have safety features installed which prevent students free access to all the programs and functions required for the course. |

|||||

|

|

|

|

|

|

|

|

In-house training: |

|||||

|

|

|

|

|

|

|

|

1. |

Please note that considerable savings, both in time and money, can be brought about by having any of the above courses presented in-house. Attractive discounts are offered. Please contact us for quotations. Terms and conditions apply. |

||||

|

|

|||||

|

2. |

Comprehensive information regarding all diplomas and courses is available on our website www.terotechnica.com |

||||

|

|

|

|

|

|

|

Course information at a glance 2018

Important note: If this table and the calendar on the right interferes with each other, press Control+minus repeatedly to reduce the font size, until you can see well enough.

|

|

Pretoria: Tel 082 855 8016

Vanderbijlpark: ((016)932-1629 7(016)932-2810 +P.O. Box 4627, Vanderbijlpark, 1900 |

|||||

|

COURSE SCHEDULE : 2018 |

||||||

|

|

|

|

|

|||

|

MERSETA accredited: Accreditation no. 17-QA/ACC/0896/13 |

||||||

|

|

|

|

|

|||

|

Course code |

Course description |

Duration Days |

Dates |

CPD Credits |

Cost |

|

|

Excl VAT |

||||||

|

C101 |

2 days |

1st course: 22 - 23 March |

R5,595 |

|||

|

2nd course: 6 - 7 August |

||||||

|

3rd course: 29 - 30 October |

||||||

|

C201 |

5 days |

1st course: 15 - 19 January |

R13,975 |

|||

|

2nd course: 9 - 13 April |

||||||

|

3rd course: 9 - 13 July |

||||||

|

4th course: 20 - 24 August |

||||||

|

5th course: 8 - 12 October |

||||||

|

6th course: 26 - 30 November |

||||||

|

C301 |

5 days |

1st course: 22 - 26 January |

R13,975 |

|||

|

2nd course: 12 - 16 March |

||||||

|

3rd course: 14 - 18 May |

||||||

|

4th course: 13 - 17 August |

||||||

|

5th course: 17 - 21 September |

||||||

|

6th course: 12 - 16 November |

||||||

|

7th course: 10 - 14 December |

||||||

|

C301X |

3 days |

1st course: 22 - 24 January |

R8,395 |

|||

|

2nd course: 12 - 14 March |

||||||

|

3rd course: 14 - 16 May |

||||||

|

4th course: 13 - 15 August |

||||||

|

5th course: 17 - 19 September |

||||||

|

6th course: 12 - 14 November |

||||||

|

7th course: 10 - 12 December |

||||||

|

C302 |

5 days |

1st course: 12 - 16 February |

R14,395 |

|||

|

2nd course: 16 - 20 April |

||||||

|

3rd course: 21 - 25 May |

||||||

|

4th course: 30 July - 3 August |

||||||

|

5th course: 15 - 19 October |

||||||

|

6th course: 3 - 7 December |

||||||

|

C501 |

Maintenance Shutdown and Project Management (Please see footnote for computer requirement) |

5 days |

1st course: 19 - 23 February |

5 |

R14,395 |

|

|

2nd course: 7 - 11 May |

||||||

|

3rd course: 23 - 27 July |

||||||

|

4th course: 1 - 5 October |

||||||

|

5th course: 19 - 23 November |

||||||

|

6th course: 10 - 14 December |

||||||

|

C702 |

Reliability Engineering in Asset Management (Please see footnote for computer requirement) |

5 days |

1st course: 16 - 20 April |

5 |

R14,820 |

|

|

2nd course: 11 - 15 June |

||||||

|

3rd course: 15 - 19 October |

||||||

|

C901 |

Maintenance Practice for Asset Management Engineers |

5 days |

1st course: 29 January - 2 February |

5 |

R13,975 |

|

|

2nd course: 9 - 13 April |

||||||

|

3rd course: 2 - 6 July |

||||||

|

4th course: 3 - 7 September |

||||||

|

C902 |

5 days |

1st course: 9 - 13 April |

5 |

R13,975 |

||

|

2nd course: 4 - 8 June |

||||||

|

3rd course: 16 - 20 July |

||||||

|

4th course: 27 - 31 August |

||||||

|

5th course: 26 - 30 November |

||||||

|

C903 |

RCM Facilitation and Analysis |

5 days |

1st course: 26 February - 2 March |

5 |

R13,975 |

|

|

2nd course: 16 - 20 April |

||||||

|

3rd course: 11 - 15 June |

||||||

|

4th course: 10 - 14 September |

||||||

|

5th course: 5 - 9 November |

||||||

|

6th course: 3 - 7 December |

||||||

|

C904 |

RCM ProAktiv, Advanced Reliability Centred Maintenance (Please see footnote for computer requirement)

Please note that this course has a pre-requirement. Students

This is to ensure that participants will adequately cope with the |

5 days |

R13,975 |

|

||

|

|

||||||

|

|

||||||

|

1st course: 22 – 26 January |

||||||

|

2nd course: 28 May - 1 June |

||||||

|

3rd course: 3 - 7 September |

||||||

|

S801 |

Reliability Centred Maintenance |

3 days |

1st course: 26 - 28 February |

3 |

R8,395 |

|

|

2nd course: 16 - 18 April |

||||||

|

3rd course: 11 - 13 June |

||||||

|

4th course: 10 - 12 September |

||||||

|

5th course: 5 - 7 November |

||||||

|

6th course: 3 - 5 December |

||||||

|

S802 |

3 days |

1st course: 26 - 28 March |

3 |

R8,395 |

||

|

2nd course: 7 - 9 May |

||||||

|

3rd course: 30 July - 1 August |

||||||

|

4th course: 19 - 21 September |

||||||

|

5th course: 12 - 14 November |

||||||

|

S803 |

5 days |

1st course: 29 January - 2 February |

5 |

R15,095 |

||

|

2nd course: 5 - 9 March |

||||||

|

3rd course: 4 - 8 June |

||||||

|

4th course: 13 - 17 August |

||||||

|

5th course: 22 - 26 October |

||||||

|

6th course: 10 - 14 December |

||||||

|

S803X |

3 days |

1st course: 30 January - 1 February |

R8,395 |

|||

|

2nd course: 6 - 8 March |

||||||

|

3rd course: 2 - 4 May |

||||||

|

4th course: 5 - 7 June |

||||||

|

5th course: 14 - 16 August |

||||||

|

6th course: 23 - 25 October |

||||||

|

7th course: 11 - 13 December |

||||||

|

S804 |

Decision Making in Maintenance |

5 days |

1st course: 5 - 9 February |

2 |

R14,820 |

|

|

2nd course: 18 - 22 June |

||||||

|

3rd course: 1 - 5 October |

||||||

|

4th course: 3 - 7 December |

||||||

|

S805 |

2 days |

1st course: 19 - 20 March |

2 |

R5,595 |

||

|

2nd course: 20 - 21 August |

||||||

|

3rd course: 1 - 2 November |

||||||

|

S808 |

3 days |

1st course: 12 - 14 February |

R8,395 |

|||

|

2nd course: 23 - 25 April |

||||||

|

3rd course: 25 - 27 June |

||||||

|

4th course: 25 - 27 September |

||||||

|

S811 |

3 days |

1st course: 16 - 18 January |

R9,550 |

|||

|

2nd course: 28 February - 2 March |

||||||

|

3rd course: 23 - 25 April |

||||||

|

4th course: 19 - 21 June |

||||||

|

5th course: 10 - 12 July |

||||||

|

6th course: 25 - 27 September |

||||||

|

S812 |

2 days |

1st course: 17 - 18 January |

R5,595 |

|||

|

2nd course: 1 - 2 March |

||||||

|

3rd course: 27 - 28 June |

||||||

|

4th course: 25 - 26 July |

||||||

|

5th course: 26 - 27 September |

||||||

|

6th course: 24 - 25 October |

||||||

|

S813 |

Economical Replacement and Life Cycle Management |

5 days |

1st course: 19 -23 February |

5 |

R14,395 |

|

|

2nd course: 23 - 27 July |

||||||

|

3rd course : 29 October - 2 November |

||||||

|

S820 |

What is Asset Management and how does it differ from |

2 days |

1st course: 3 - 4 April |

R5,595 |

||

|

2nd course: 6 - 7 August |

||||||

|

S821 |

3 days |

1st course: 19 - 21 June |

R8,395 |

|||

|

2nd course: 10 - 12 October |

||||||

|

S822 |

3 days |

1st course: 9 - 11 May |

R8,395 |

|||

|

Diploma in Maintenance Management |

For comprehensive information on our choice of 5 diplomas, |

R55,200 |

||||

|

please visit our website www.terotechnica.com |

||||||

|

|

|

|

|

|

|

|

|

Footnote: Students enrolling for these courses, C501, C702, C901, C903, C904, S801, S804 and S813, must be in possession of their own laptop computers. Computers supplied by employers often have safety features installed which prevent students free access to all the programs and functions required for the course. |

||||||

|

|

|

|

|

|

|

|

|

In-house training: |

||||||

|

|

|

|

|

|

|

|

|

1. |

Please note that considerable savings, both in time and money, can be brought about by having any of the above courses presented in-house. Attractive discounts are offered. Please contact us for quotations. Terms and conditions apply. |

|||||

|

|

||||||

|

2. |

Comprehensive information regarding all diplomas and courses is available on our website www.terotechnica.com |

|||||

|

|

|

|

|

|

|

|

C301X: Maintenance Planning Fundamentals

If one compares maintenance to the human body, maintenance planning provides the thinking capacity that determines what work to do, and when, while the artisans provide the doing capacity of the hands and feet, and supervisors provide the controlling function of the brain, steering the hands and feet.

If one compares maintenance to the human body, maintenance planning provides the thinking capacity that determines what work to do, and when, while the artisans provide the doing capacity of the hands and feet, and supervisors provide the controlling function of the brain, steering the hands and feet.

Because nothing in life takes place before it has been thought through, no worthwhile maintenance task can take place before planning (naturally including any planning done by supervisors and artisans).

No worthwhile maintenance task can take place without good planning

Maintenance planning fulfils a crucial role in the organisation. Maintenance success is absolutely dependent on good scheduling of maintenance work, proper task planning, and timely procurement of parts and materials. The Maintenance Planner plays a critical role in achieving this essential outcome.

Maintenance planning fulfils a crucial role in the organisation. Maintenance success is absolutely dependent on good scheduling of maintenance work, proper task planning, and timely procurement of parts and materials. The Maintenance Planner plays a critical role in achieving this essential outcome.

The C301 Maintenance Planning course thus has as its purpose to prepare Maintenance Planners for this role. This includes training in the various scheduling techniques, such as simple time slot scheduling, detailed network scheduling of maintenance shutdowns and projects, as well as batch workshop scheduling. It also includes training in task planning methods, procurement methods, use of maintenance systems, task flow optimisation, maintenance information analysis, and the support of maintenance management through well defined and formatted reporting.

This course, which is a shortened version of the C301 Maintenance Planning course, leaves out the content on Systems (day 4 of C301) and Management Support (day 5 of C301). It thus addresses the most critical planning skills, i.e. scheduling, task planning and procurement. Some organisations may perhaps feel that their planners need not understand the deeper systems issues, and may also not require their planners to support the business' managers with pointed information. They may thus prefer this simplified course to the more comprehensive training.

The course is extremely hands-on, allowing candidates to practice the skills learnt through practical application during four to five group assignments per day. This is augmented by an application project following course completion.

Course Content

|

Module 1

|

Module 2

|

Module 3

|

|

Credits 10*, level 5** * The course comprises 50 hours of study, of which 24 hours are in class, with a further 10 hours of private study, and 16 hours for the assignment. **Occupational Certificate level |

|

Who Should Attend

The course is intended for maintenance planners, maintenance supervisors, artisans and those who manage them.

The reason for including the wording 'those who manages them' in the sentence above is that we often find that some class of Asset Management / Maintenance people are sent on courses without the person managing them being able to activate their newly acquired knowledge after the course. What rather happens is that they are managed exactly in the same way as before the course, which often leads to the course not having the required effect.

Artisans are also specifically added above as the effect of maintenance planning and the information fed back to the Computerised Maintenance System is to a large extent dependent on their knowledgeability of, and support to, the Maintenance Planning function.

S803X: Root Cause Failure Analysis Fundamentals

Root Cause Analysis is one of the most potent tools in the fight against failure

Root Cause Analysis is used in a routine way in most medical situations. It is recognised that a symptom has an immediate cause, which can in turn be caused by a deeper seated problem. Physicians also understand that you cannot just jump in and start treating the symptoms. You need to stop to consider whether there's actually a deeper problem that needs your attention.

Root Cause Analysis is used in a routine way in most medical situations. It is recognised that a symptom has an immediate cause, which can in turn be caused by a deeper seated problem. Physicians also understand that you cannot just jump in and start treating the symptoms. You need to stop to consider whether there's actually a deeper problem that needs your attention.

If you only address the symptoms – what you see on the surface – the problem will almost certainly happen again... which will lead you to re-address the same symptoms, again, and again, and again. If, instead, you look deeper to find out why the problem is occurring, you can remedy the underlying systems and processes that cause the problem.

We in maintenance also work with 'patients', machine patients. In the same way as with patients in the medical case, we have to find problems through the use of Root Cause Analysis.

Root Cause Analysis seeks to identify the origin of a problem. It uses a specific set of steps, with associated tools, to find the primary cause of the problem, so that you can:

- Determine what happened.

- Determine why it happened.

- Decide on an action to reduce the risk of it happening again.

Root Cause Analysis typically leads to one or more of the following three basic types of causes:

Root Cause Analysis typically leads to one or more of the following three basic types of causes:

- Physical causes – something physical failed or stopped working.

- Human causes – somebody did something wrong, made a judgment error.

- Organisational causes – a system, process, or policy that people use to make decisions or do their work is inadequate.

This simplified version of the full S803 Root Cause Failure Analysis course aims to provide all the information to be able to perform a full root cause analysis, but leaving out the very worthwhile part on using the Herman Brain Dominance instrument to optimise your team's problem solving capabilities, as well as the final comprehensive practical workshop. This is intended for persons that need the knowledge regarding RCFA, but without the need for optimise the use of the method, and the practice afforded by the final workshop.

The accent of the course is on practical application through group work. The purpose of this is for students to internalise the method well.

Course Content

|

Module 1 – Failure Cause Analysis Fundamentals

|

Module 2 – Principles of RCFA

|

Module 3 – Getting RCFA to Work

|

Who Should Attend

The course is intended for maintenance people who need to cope with maintenance problem situations.

|

Credits 8*, level 5**

* The course comprises 40 hours of study, of which 24 hours are in class, with a further 16 hours for the assignment. **Occupational Certificate level |

Course information at a glance 2017

Course prices and other summary information - 2017

| Course Code | Course Description | Duration | Course Dates | CPD Points | Cost (Ex VAT) |

| C101 | Asset Management for Artisans | 2 days |

1st course: 24 to 25 April 2nd course: 3 to 4 August 3rd course: 13 to 14 November |

R 5 320 | |

| C201 | Asset Management for Maintenance Supervisors | 5 days |

1st course: 23 to 27 January 2nd course: 6 to 10 March 3rd course: 5 to 9 June 4th course: 14 to 18 August 5th course: 27 November to 1 December |

R 13 307 | |

| C301 | Maintenance Planning | 5 days |

1st course: 23 to 27 January 2nd course: 13 to 17 March 3rd course: 8 to 12 May 4th course: 3 to 7 July 5th course: 28 August to 1 September 6th course: 16 to 20 October 7th course: 20 to 24 November |

R 13 307 | |

| C301X | Maintenance Planning Fundamentals | 3 days |

1st course: 18 to 20 April 2nd course: 12 to 14 June 3rd course: 1 to 3 August |

R 7 982 | |

| C302 | Advanced Maintenance Planning | 5 days |

1st course: 6 to 10 February 2nd course: 22 to 26 May 3rd course: 10 to 14 July 4th course: 11 to 15 September 5th course: 13 to 17 November |

R 13 709 | |

| C501 |

Maintenance Shutdown and Project Management Important: See footnote regarding notebook computers |

5 days |

1st course: 30 January to 3 February 2nd course: 29 May to 2 June 3rd course: 30 October to 3 November |

5 | R 13 709 |

| C702 |

Reliability Engineering in Asset Management Important: See footnote regarding notebook computers |

5 days |

1st course: 8 to 12 May 2nd course: 23 to 27 October |

5 | R 14 110 |

| C901 |

Maintenance Practice for Asset Management Engineers Important: See footnote regarding notebook computers |

5 days |

1st course: 6 to 10 March 2nd course: 4 to 8 September |

5 | R 13 307 |

| C902 | Leadership in Asset Management | 5 days |

1st course: 13 to 17 February 2nd course: 15 to 19 May 3rd course: 17 to 21 July 4th course: 6 to 10 November |

5 | R 13 307 |

| C903 |

Important: See footnote regarding notebook computers |

5 days |

1st course: 3 to 7 April 2nd course: 26 to 30 June 3rd course: 14 to 18 August 4th course: 2 to 6 October |

5 | R 13 307 |

| C904 |

RCM ProAktiv (advanced Reliability Centred Maintenance) Important: See footnote regarding notebook computers Important Note: Course participants must have either an engineering degree (B.Eng., BSc (Eng) or B.Tech), or must have successfully completed both C702 and C903 to qualify for registration for this course. This is to ensure that participants will adequately cope with the course content. Exceptions to this rule is possible, but will have to be suitably motivated. |

5 days |

1st course: 5 to 9 June 2nd course: 20 to 24 November |

R 13 307 | |

| S801 |

Reliability Centred Maintenance Important: See footnote regarding notebook computers |

3 days |

1st course: 3 to 5 April 2nd course: 26 to 28 June 3rd course: 14 to 16 August 4th course: 2 to 4 October |

3 | R 7 982 |

| S802 | Asset Management for Executives | 3 days | To be presented on request for groups of at least 4 delegates |

3 | R 7 982 |

| S803 | Root Cause Failure Analysis | 5 days |

1st course: 20 to 24 February 2nd course: 19 to 23 June 3rd course: 18 to 22 September 4th course: 27 November to 1 December |

5 | R 14 372 |

| S803X | Root Cause Failure Analysis Fundamentals | 3 days |

1st course: 3 to 5 May 2nd course: 26 to 28 September |

R 7 982 | |

| S804 |

Decision-making in Maintenance Important: See footnote regarding notebook computers |

5 days |

1st course: 27 February to 3 March 2nd course: 24 to 28 July 3rd course: 9 to 13 October |

2 | R 14 110 |

| S805 | Maintenance Control | 2 days | 1st course: 17 to 18 July | 2 | R 5 320 |

| S808 | Asset Management Logistics | 3 days |

1st course: 10 to 12 April 2nd course: 18 to 20 September |

R 7 982 | |

| S811 | Water Treatment Plant Operation and Maintenance | 3 days | To be presented on request for groups of at least 4 delegates |

R 9 095 | |

| S812 | Road Maintenance | 2 days | To be presented on request for groups of at least 4 delegates |

R 5 320 | |

| S813 |

Assets: Economical Replacement and Life Cycle Management Important: See footnote regarding notebook computers |

5 days |

1st course: 27 to 31 March 2nd course: 11 to 15 September |

5 | R 13 709 |

| S820 | What is Asset Management and how does it differ from Maintenance? | 2 days | 3 to 4 April | R 5 320 | |

| S821 | Understanding ISO 55000 | 3 days | 24 to 26 July | R 7 982 | |

| S822 | Implementing ISO 55000 | 3 days | 6 to 8 November | R 7 982 | |

|

Diploma in Maintenance Management For comprehensive information on our choice of 5 diplomas, please click on the link above |

R 52 579 | ||||

| Footnote: |

Students enrolling for the following courses must be in possession of their own laptop computers: C501, C702, C901, C903, C904, S801, S804 and S813 The reason is that computers supplied by employers often have safety features installed which prevent students free |

||||

| In-house training |

|

||||

S822: Implementing ISO 55000

ISO 55000 is about using the organisation’s assets for maximal gain

Important Note: If unsure of the background to the ISO 55000 standard, read the "S820: What is Asset Management and how does it differ from Maintenance” page.

The discipline of Asset Management is increasingly important. In Asset Management full regard for achieving maximum benefit from the organisations’ assets is intended. Such expertise draws from all functions within an organisation: from business, financial, human resources, as well as operations and maintenance management. It is particularly challenging, therefore, to gain a good understanding of the discipline across the whole breadth of the knowledge base.

The ISO 55000 standard assists asset intensive businesses to achieve excellence in Asset Management. This is of critical importance when dealing with shareholders and regulators, who expect first-class results from the business’ assets.

The S822 course is meant to assist the organisation in implementing the ISO 55000 standard. It assumes that the participant understands what the ISO 55000 standards entail (per the S821 course).

Benefits of implementing ISO 55000 includes:

- The application of an asset management system provides assurance that the organisation's objectives can be achieved consistently and sustainable over time.

- Asset management enables an organisation to examine the need for, and performance of, assets and asset systems at different levels.

- Aligning the asset management objectives with the organisational objectives, as well as linking asset reports to financial reports, improves the organisation’s effectiveness and efficiency.

- Additional benefits:

- Improved financial performance

- Managed risk

- Improved organisational sustainability

- Improved financial performance

Course Content

|

Module 1

|

Module 2

|

Module 3

|

Who Should Attend

Maintenance Managers, Maintenance Engineers, Reliability Engineers, Production Managers, Business Managers.

|

Credits 8*, level 6**

* The course comprises 40 hours of study, of which 24 hours are in class, with a further 16 hours for an assignment. **Higher Diploma level |

|

S821: Understanding ISO 55000

ISO 55000 is about using the organisation’s assets for maximal gain

Important Note: If unsure of the background to the ISO 55000 standard, read the "S820: What is Asset Management and how does it differ from Maintenance" page.

The discipline of Asset Management is increasingly important. In Asset Management full regard for achieving maximum benefit from the organisations’ assets is intended. Such expertise draws from all functions within an organisation: from business, financial, human resources, as well as operations and maintenance management. It is particularly challenging, therefore, to gain a good understanding of the discipline across the whole breadth of the knowledge base.

The ISO 55000 standard assists asset intensive businesses to achieve excellence in Asset Management. This is of critical importance when dealing with shareholders and regulators, who expect first-class results from the business’ assets.

In deciding whether Asset Management is for your organisation, consider the following questions:

- Do you understand the risk profile associated with your asset portfolio and how this will change over time?

- Can you demonstrate the business consequences of reducing/increasing your capital investment or maintenance budgets by 10% over the next five years?

- Can you justify your planned asset expenditures to external stakeholders?

- Can you easily identify which investment projects to defer when there are funding or cash flow constraints?

- Do you have the appropriate asset data and information to support your Asset Management decision-making?

- Do you know if your people have the right competencies and capabilities to manage your assets?

- Do you know which Asset Management activities to outsource?

The ISO 55000 set (ISO 55000, ISO 55001, ISO 55002) of International Standards is primarily intended for use by:

- Those involved in the establishment, implementation, upkeep and improvement of an asset management system

- Those involved in delivering asset management activities and services

- Those needing to assess an organisation’s ability to meet legal, regulatory and contractual requirements

Course Content

|

Module 1

|

Module 2

|

Module 3

|

Who Should Attend

Maintenance Managers, Maintenance Engineers, Reliability Engineers, Production Managers, Business Managers.

|

Credits 8*, level 6** * The course comprises 40 hours of study, of which 24 hours are in class, with a further 16 hours for an assignment. **Higher Diploma level |

|

S820: What is Asset Management and how does it differ from Maintenance?

Critical changes affecting Maintenance and Production people

Production as well as service organisations have traditionally discharged their duty towards their owners / founders /stakeholders by operating and maintaining production/service assets. For this purpose there existed a production/service department and a maintenance department in most firms.

Since the sixties of the previous century there was a progressive realisation that production assets need to be managed comprehensively by production organisations. Maintaining them is not the total answer. The idea of Physical Asset Management (mostly simply called Asset Management) was conceived.

Asset Management includes Maintenance, but much more than that. It broadly includes the following four main stages:

- Asset conceptualisation, design, development, and production.

- Asset (and support infrastructure) selection, procurement, and installation.

- Asset operation and maintenance

- Asset disposal

This led to the British PAS 55 Standard (2003, updated in 2008), followed by an International set of standards, called ISO 55000. These address the need for developing the typical organisation’s Maintenance function to a full blown Asset Management Function.

The questions now asked by most Maintenance (as well as Production) people are:

- What is the difference between what I have been doing and what I am supposed to be doing in future?

- Will these standards really contribute to a better future for our businesses?

- What is the real difference between Maintenance and Asset Management?

- What do I have to do?

The present course intends answering these questions, so that business managers (production and maintenance) can start planning for the new future specified by these standards.

Can Maintenance and Production people disregard these changes?

These changes will have at least as great an effect as that of the various safety, quality, and environmental standards. It is critical to build an understanding of these changes now and start planning for the future.

Course Content

|

Module 1 (Day 1) - Overview of the relationship between Maintenance and Asset Management

|

Module 2 (Day 2) - The deeper relationship between Maintenance and Asset Management

|

Who Should Attend

Maintenance Managers, Maintenance Engineers, Reliability Engineers, Production Managers, Business Managers.

|

Credits 6*, level 6** * The course comprises 30 hours of study, of which 16 hours are in class, with a further 14 hours for an assignment. **Higher Diploma level |

|